— February 22nd, 2024 —

Ethical car designers will quickly discover that corruption in the car industry goes way beyond manufacturers' faked emission-tests; their historical running of the concentration camps; and the children they now force to work in the cobalt, mica, and lithium mines. In fact, the corruption in Car Land begins the moment an engineer switches on a computer and loads her CAD (Computer Aided Design) software.

All modern computer processors are backdoored-by-design, and so air-gapping (physically disconnecting from the internet) all your engineering computers is the only rational solution.

Intel's 'Management Engine' and AMD's 'Platform Security Processor' openly spy on everything you do on your computer, reporting this data back to whoever has keys to the CPU backdoors.

The larger automobile conglomerates are inextricable from the state. National Socialism was essentially corporatism. Therefore, the problem can be stated simply: If you plan to design and engineer products, then it is foundational to ensure that your competitors cannot steal your designs.

If you are working in the car industry, then your competitors are state-level combatants. In other words: Governments.

It is no accident that car-manufacturers are able to fake their emissions-tests and build unchecked monopolies: These car companies 'own' vast swathes of the political apparatus. This gives these conglomerates access to surveillance systems; the Intel and AMD backdoors; and (you guessed it) access to your engineering computers.

Remember, many of these car companies are currently lithium-cobalt child-slavers; several have authentically Nazi-origins.

Volkswagen famously built, and ran, the Nazi concentration-camps. More recently, Volkswagen has lied about the performance of their car engines; multiple times, in multiple countries. Volkswagen fake their emissions-tests regularly; poisoning our shared air-supply. Volkswagen is, provably, psychotically-unable to stop 'gassing' our communities. They are mass-murderers.

As is clear by now, this 'Automobile Establishment' will have no qualms about reading stolen information from your computer screen, assisted by the government(s) they think they own. They have no morals whatsoever. Stealing information from your engineering computers is natural to them; they think nothing of it.

Airgapping all engineering-computers should be routine if you are working in the independent automotive-design field. To 'airgap' a computer means to remove any wifi, ethernet or bluetooth hardware from the system and to ensure the computer is completely disconnected from the internet or other exploitable network-connection.

It is not enough simply to disconnect from a wifi network, or to pull out the ethernet cable. You must choose a motherboard that does not include wireless and/or bluetooth hardware. Or, you must unplug (or physically de-solder) these wireless-networking components from the motherboard. There is no software-fix because the surveillance hardware can lie to the software; claiming to be inactive when it is, in fact, gathering data.By air-gapping a system, you ensure that (although the CPU is backdoored) the computer can no longer spy on you because it cannot report its spying to anyone. Your back-doored CPU will continue to monitor your work, but it will be trapped; unable to transfer this information out to the Automobile Establishment and their cronies in government(s).

Here, we should touch briefly on the issue of the ethics of CAD (Computer Aided Design) computers themselves. Almost every modern computer is manufactured in a Communist dictatorship, often by children. This is, after all, the reason companies manufacture in this region: It is cheap to manufacture in the 'Slave Zone' because there are zero human rights, and children are often used as labor.

Semi-ethical options do exist, but they take some hunting down. For example, Raspberry Pi claims to manufacture their computer boards in the UK. Although you might consider this an underpowered computer, it is perfectly sufficient for running software like the excellent Solvespace (for parametric modeling) or Blender (for visualization work).

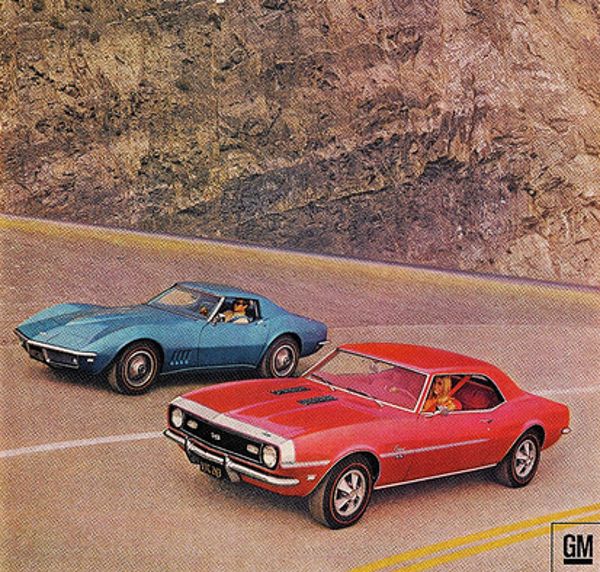

Remember that most of the greatest cars ever designed came from an era before desktop computers. You should consider eliminating computers as much as possible from your engineering workflow. They tend to destroy creativity and generate lazy, derivative designs. The engineers who worked on the 1968 Corvette Stingray (pictured below in blue) went nowhere near a computer. This car, like others of its era, remains a design masterpiece.

If you absolutely must use a 3D workstation for your automotive design, then the closest thing to an ethical PC appears to be some of those made by Fujitsu, which are "made" in Germany and Japan. Sadly, this may simply mean that these computers meet a percentage-level of non-Slave-Zone parts and/or assembly processes, and not that they are entirely "made" in their claimed country of origin.

Similarly, Eizo claim to "make" their screens in Japan, yet closer inspection reveals this is not entirely accurate. It is fairer to say that these screens have met a threshold-percentage of parts (and assembly processes) that allows the manufacturer to legally make that claim.

This information is not given lightly: It took many months to figure out that Raspberry Pi, Fujistu, and Eizo are the closest thing resembling ethical options. Most country-of-manufacture information is hidden. Most major search engines are 'gamed' to stop the consumer from avoiding the profitable 'Slave Zone' manufacturers.

The elephant in the room of the computer industry is this: That most of our computers are made by slaves, and profit the slave-masters.

Even a Fujitsu PC contains many Slave-Zone-sourced parts. The balance, we hope, shifts towards ethical manufacture.

A second-hand Fujitsu and Eizo screen is perhaps the only option for CAD designers who don't want to fund slavery. Even then, you may be enabling the purchase of a new, wholly unethical, computer by whoever you buy the second-hand machine from.

Finally, there is the question of software. Given the association between the former-head of one major operating system manufacturer and Jeffrey Epstein, nobody with any sense of morality can use his product. The other major operating system (and computer) manufacturer is a notorious child-slaver, so again, we can rule them out. The solution here is obvious: Linux.

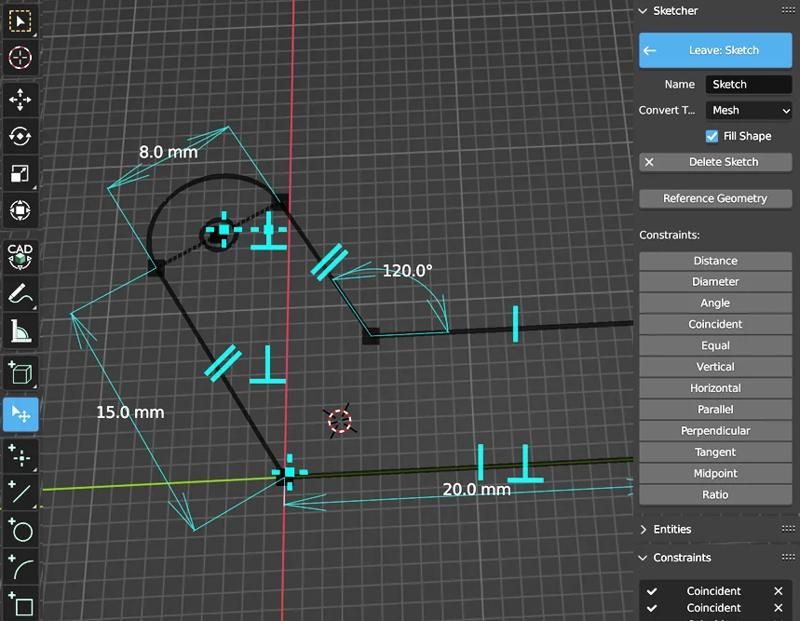

If you haven't tried Linux in a few years, you will be surprised by how it has made strides past everything else. Now there is even a project in the works to connect the Solvespace engine to Blender. The project is called CAD Sketcher, and it drives parametric modeling on free, open-source software to vibrant new heights.

More impressive still, however, is the work of a developer called RealThunder. This hotshot-coder is firing on all turbines and has produced a fork of FreeCAD that outshines the original. RealThunder's fork includes a topological naming feature and other slick hacks.

In RealThunder's own words, "I am an extremely efficient coder. In fact, my coding pace is probably too fast for FreeCAD upstream." That's fighting talk. Some of his software-design work is animated below.

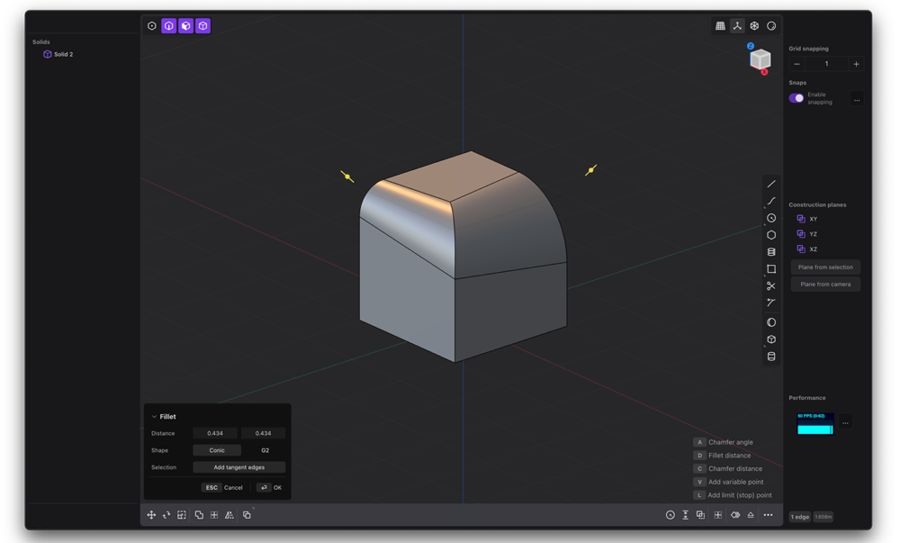

Young car-designers who have switched to Linux may also enjoy a piece of software called Plasticity. Although not strictly open-source, Plasticity should be run on your air-gapped engineering machine(s) anyway; eliminating any security risk.

Plasticity is a delight to use, combining the world-class Parasolid geometry engine with a workflow that borrows extensively from Blender. Its developers call it "CAD for artists", and I agree.

The heart that beats behind the scenes of Plasticity is the same that powers 'establishment' CAD tools like SolidWorks and Siemens NX. I am referring here to the robust Parasolid geometry kernel that Plasticity is based on. This geometry-kernel's powerful capabilities will be familiar to anyone who has already used a professional-grade CAD system.

Plasticity is currently one of my favorite parametric-modeling tools during my work for the Gyozu prototyping and engineering company. However, like other engineers on our teams, I avoid touching a computer until the very end of the design process. All of my concept work, and drafting, is done with pencil and paper. I refuse to become another automobile-CAD-head; a sad victim of our culture's zombie-trance; staring blankly into a computer screen; producing trash.

The Plasticity software is both Linux-compatible, and entirely happy to run air-gapped for months on end. These are rare qualities in the 'professional' CAD space. Most other 'professional' CAD software likes to 'phone home' via the internet; making it entirely unsuitable for any serious work dethroning the legacy car manufacturers.

Given that open-source has overtaken the industry: What now for the legacy, surveillance-based CAD tools that the automobile industry has come to rely on? What now for our cultural compulsion to reach for a computer rather than a pencil and paper?

Look around you on the streets. Do these modern cars look good? In my opinion, they are irredeemably horrible; bulbous and insectoid; the dreary sum of an engineering 'degree', a wind-tunnel, and a copy of AutoCAD. All the tools that created these cars should be burned at the digital stake.

Form does not merely follow function; it also follows the tools we use to create the things we build. We have seen what happens when CAD and wind-tunnels become our core tools for self-expression in the automobile industry: Our cars turn to ugly shit.

Today's collapsing automobile-industry is a decrepit monster. Whatever tools were used to build this industry, and the cars it produced, were not fit for purpose. It's time for something new.

The writer, Phoenix Kaspian (formerly Chris Stevens), is not affiliated in any way with any products or companies mentioned in this article other than Gyozu; the prototyping company. An earlier version of this article was published in Itsfoss, the world's leading Linux-software reviews magazine.

The article published above was updated in 2024 to include relevant-information about recent major developments in CAD software, and to strengthen the article's position against the legacy car industry. The original article can be read on the Itsfoss website.